Exploring Laser Machining Innovations at China Import and Export Fair 2025

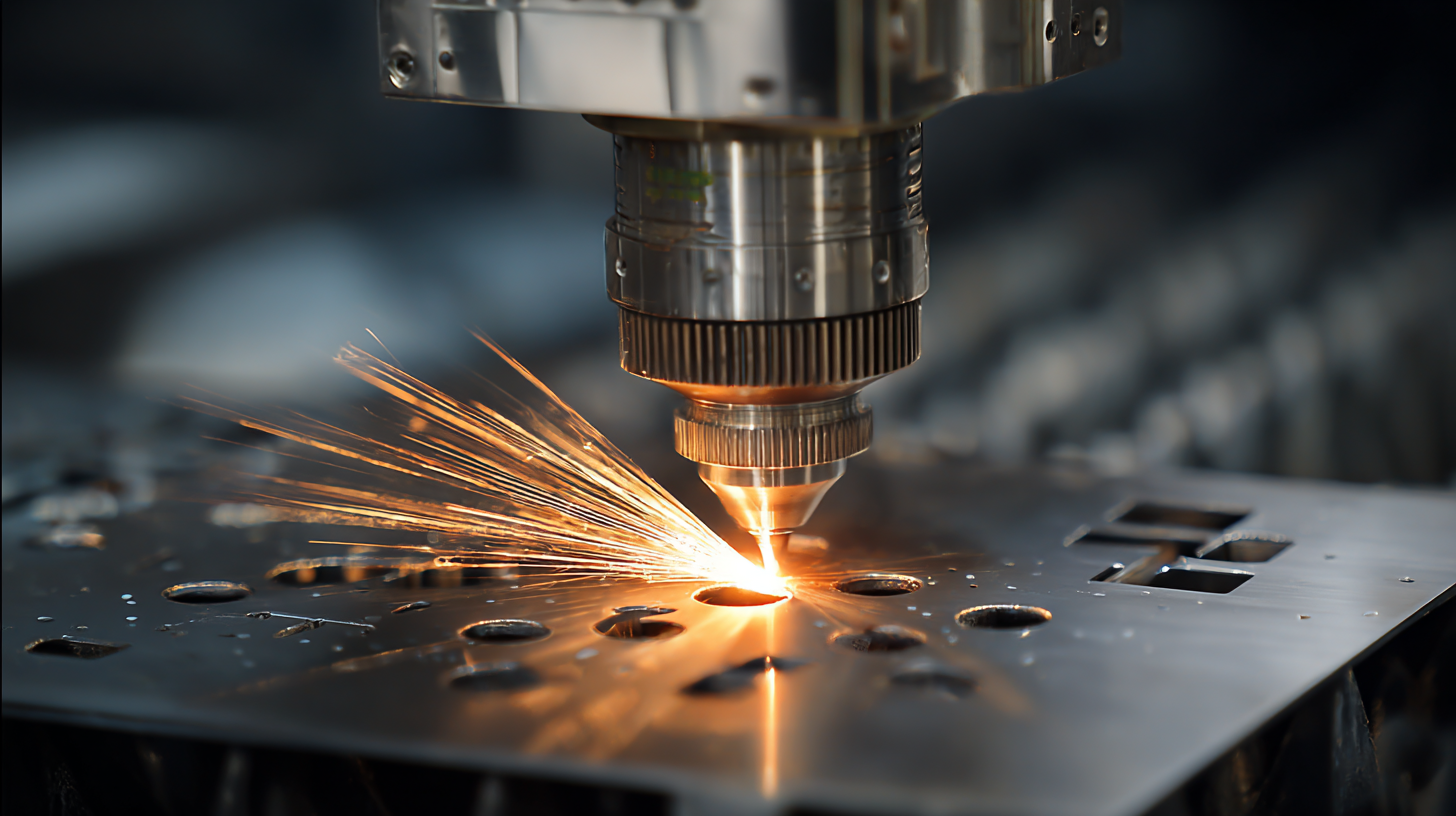

As the global manufacturing landscape continually evolves, laser machining has emerged as a pivotal technology in precision manufacturing. At the 2025 China Import and Export Fair (Canton Fair), attendees will witness groundbreaking innovations that redefine the capabilities of laser machining. According to a recent market report by Mordor Intelligence, the global laser machining market is projected to grow at a compound annual growth rate (CAGR) of over 7% through 2026, driven by increasing demand for high-precision components across various industries, including automotive and aerospace.

As the global manufacturing landscape continually evolves, laser machining has emerged as a pivotal technology in precision manufacturing. At the 2025 China Import and Export Fair (Canton Fair), attendees will witness groundbreaking innovations that redefine the capabilities of laser machining. According to a recent market report by Mordor Intelligence, the global laser machining market is projected to grow at a compound annual growth rate (CAGR) of over 7% through 2026, driven by increasing demand for high-precision components across various industries, including automotive and aerospace.

This event will serve as a platform for showcasing advanced laser machining techniques, highlighting their role in enhancing productivity and achieving intricate designs that were previously unattainable. With an estimated market value surpassing $5 billion, laser machining is vital for promoting efficient manufacturing processes and sustainable practices. The 138th Canton Fair is set to be an essential gathering for industry leaders, providing invaluable insights into the future of laser machining technology and its applications.

Innovative Laser Machining Technologies Showcased at the 138th Canton Fair

The 138th Canton Fair is set to be a remarkable platform for showcasing the latest advancements in laser machining technologies. As industries increasingly seek innovative solutions for precision manufacturing, the fair highlights groundbreaking applications that enhance efficiency and accuracy. Leading companies are expected to present state-of-the-art laser cutting, welding, and engraving systems that push the boundaries of traditional machining methods. These innovations not only improve production speeds but also significantly reduce material waste, making manufacturing processes more sustainable.

Exhibitors will demonstrate how these advanced laser technologies are revolutionizing various sectors, including automotive, aerospace, and electronics. Attendees can look forward to live demonstrations that illustrate the versatility and adaptability of laser machining equipment. With the growing trend toward automation, the integration of smart technologies alongside laser systems promises to streamline operations further, enabling manufacturers to meet the challenges of modern production demands. This year's Canton Fair promises to be a pivotal event for anyone interested in the future of manufacturing technology.

Key Industry Players in Laser Machining Present at the 2025 Event

The 2025 China Import and Export Fair is set to be a key event for the laser machining industry, showcasing the latest innovations and technologies that are driving the sector forward. Major players such as Trumpf, Coherent, and Han's Laser are expected to present their cutting-edge solutions, significantly impacting manufacturing efficiency and precision. According to a recent industry report by MarketsandMarkets, the global laser machining market is projected to grow from $5.6 billion in 2020 to $9.8 billion by 2025, reflecting an impressive CAGR of 11.6%. This growth is fueled by the increasing demand for laser technology in sectors like automotive, aerospace, and electronics.

Tips for attendees: Engage with industry leaders during the exhibition to understand the nuances of laser technology. Participating in workshops and presentations can provide deeper insights into machine capabilities and future trends. Networking with experts will also open up potential collaborations that could enhance your own operations.

At the fair, visitors can witness firsthand the advancements in laser solutions, including automation and AI integration, which are revolutionizing production lines. The presence of international exhibitors underscores the global shift toward sustainable and efficient manufacturing practices. By leveraging these innovations, businesses can not only optimize production but also reduce waste, aligning with the growing emphasis on sustainability in industrial operations.

Advancements in Laser Precision: Revolutionizing Manufacturing Processes

The advancements in laser precision technology, highlighted at the China Import and Export Fair 2025, signify a paradigm shift in manufacturing processes. As industries strive for greater efficiency and accuracy, innovations in laser machining are proving to be transformative. These advancements allow for intricate designs and improved material handling, ultimately enhancing the productivity and quality of manufactured goods. By harnessing the power of high-precision lasers, manufacturers can achieve previously unattainable tolerances and surface finishes.

In parallel, breakthroughs in related fields such as single-cell proteomics reflect a growing trend toward precision in scientific research and industrial applications. Techniques like the “Chip-Tip” method are pushing the boundaries of analysis, much like laser technology is revolutionizing manufacturing. The ability to conduct deep, nuanced analysis in both scientific and industrial contexts demonstrates a broader movement towards integrating precision technologies across various domains. This synergy fosters innovation, paving the way for refined processes that not only enhance productivity but also deepen our understanding of complex systems, from biological functions to manufacturing operations.

Exploring Laser Machining Innovations at China Import and Export Fair 2025 - Advancements in Laser Precision: Revolutionizing Manufacturing Processes

| Innovation | Description | Impact on Manufacturing | Year of Introduction |

|---|---|---|---|

| Fiber Laser Technology | Utilizes fiber optics to deliver high-power laser beams with increased efficiencies. | Enhanced cutting speeds and reduced operational costs. | 2021 |

| Ultrafast Laser Machining | Employs short pulse lasers to create precise micro-machining applications. | Allows for intricate designs and minimal thermal effects on materials. | 2022 |

| Hybrid Laser Processing | Combines laser with other machining processes for enhanced capabilities. | Increases versatility and expands application range. | 2023 |

| Smart Laser Machining Systems | Integrates AI and machine learning for process optimization and predictive maintenance. | Improves efficiency and reduces downtime in manufacturing processes. | 2024 |

Sustainable Practices in Laser Machining Highlighted at the Fair

At the upcoming China Import and Export Fair 2025, the spotlight will be on sustainable practices in laser machining, which has become a cornerstone of innovation in manufacturing. The trend of integrating sustainability into production processes is growing rapidly, as evidenced by recent reports indicating that the global market for sustainable manufacturing is projected to reach over USD 5 trillion by 2027. This shift highlights an industry-wide commitment to reduce environmental impact while enhancing operational efficiency.

Organizations are increasingly utilizing advanced technologies such as AI and automation, which are reshaping traditional machining and manufacturing paradigms. According to industry analyses, automation alone is expected to account for a significant portion of machine tool market growth, with sustainability driving new standards. Recent exhibitions, including those focused on denim production, have showcased how innovative practices can dramatically reduce resource consumption, such as slashing water usage in textile processing by up to 95%. This trend not only meets consumer demand for eco-friendly products but also opens new avenues for cost savings and efficiency improvements across various sectors.

Innovations in Laser Machining at China Import and Export Fair 2025

This chart showcases the performance metrics of laser machining innovations highlighted at the China Import and Export Fair 2025. Key dimensions include efficiency, sustainability, cost-effectiveness, speed, and flexibility, reflecting the advancements in sustainable practices in the laser machining industry.

Networking Opportunities for Laser Technology Experts at the Canton Fair

The Canton Fair, officially known as the China Import and Export Fair, serves as a dynamic platform for innovators and professionals in various industries, including laser technology. In 2025, the fair will feature a focused segment dedicated to exploring advancements in laser machining. This event not only showcases cutting-edge technologies but also facilitates networking opportunities for experts in the field. Attendees can engage in discussions, share insights, and explore potential collaborations that can drive the laser technology sector forward.

The Canton Fair, officially known as the China Import and Export Fair, serves as a dynamic platform for innovators and professionals in various industries, including laser technology. In 2025, the fair will feature a focused segment dedicated to exploring advancements in laser machining. This event not only showcases cutting-edge technologies but also facilitates networking opportunities for experts in the field. Attendees can engage in discussions, share insights, and explore potential collaborations that can drive the laser technology sector forward.

Networking at the fair is crucial for laser technology experts looking to expand their knowledge and professional connections. With industry leaders, researchers, and startups in attendance, participants will have the chance to attend workshops, panel discussions, and demonstration sessions. These interactions will enable attendees to stay updated on the latest trends, share best practices, and foster partnerships that could lead to innovative solutions in laser machining. The Canton Fair thus stands as an essential gathering for those dedicated to advancing the possibilities of laser technologies.

Related Posts

-

Exploring Laser CNC Innovations at the 2025 China 138th Import and Export Fair

-

Unlocking the Power of Laser Etching in Modern Manufacturing

-

Emerging Trends in Stainless Steel Laser Cutting Technologies at the 138th Canton Fair 2025 in China

-

Exploring Market Trends: Stainless Steel Laser Engraving at the 138th Canton Fair 2025