The Ultimate Guide to Choosing the Best CNC Engraver for Your Projects

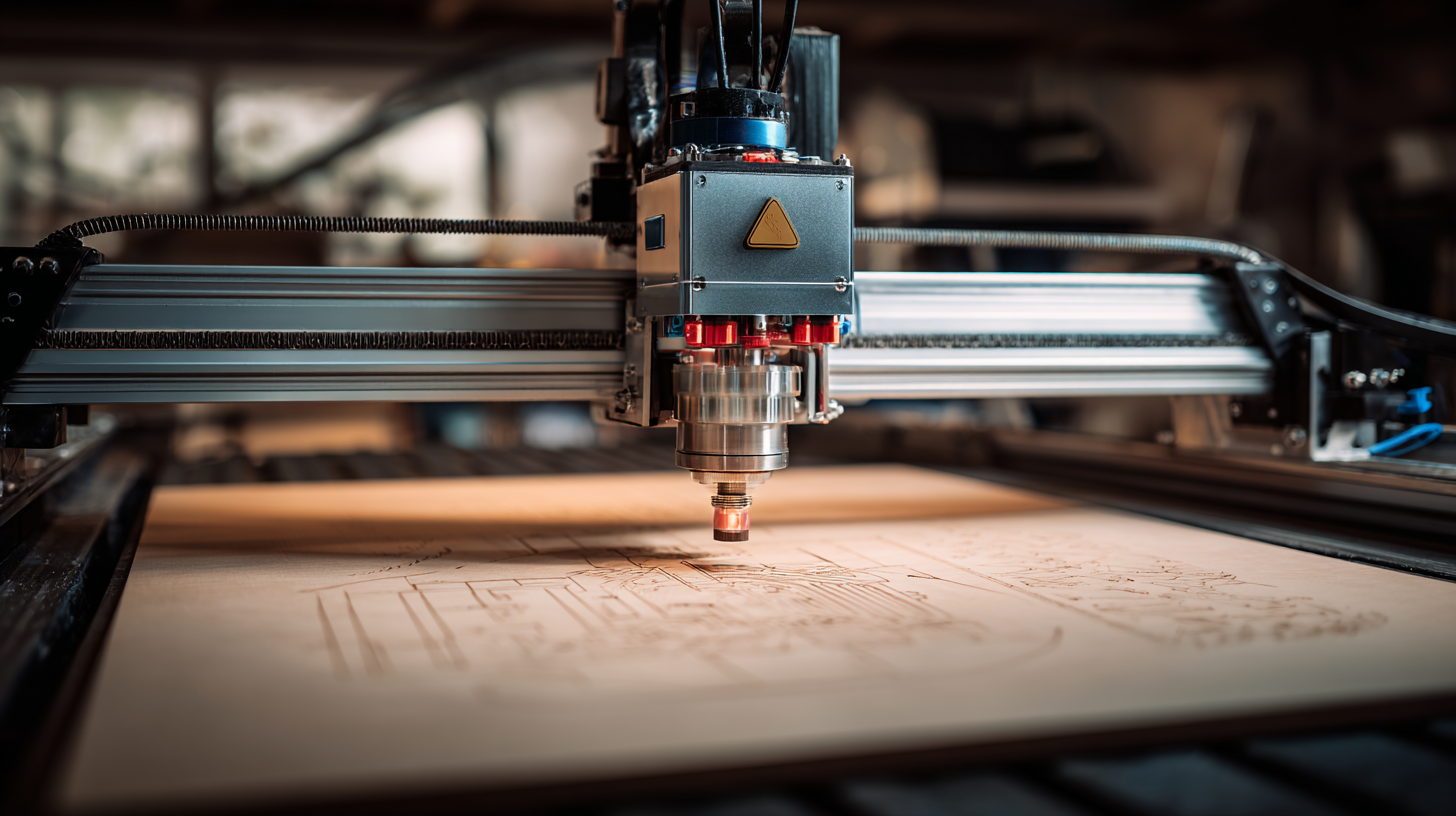

Choosing the right CNC engraver is crucial for achieving precision and efficiency in various projects, whether for personal or professional use. According to a recent industry report by MarketsandMarkets, the global CNC machine market is projected to reach $100 billion by 2026, driven by the growing demand for automation and advanced manufacturing processes. As businesses increasingly adopt CNC technology, understanding the key features and specifications of CNC engravers has become essential. These machines not only enhance the quality of engravings but also significantly reduce production time, making them an indispensable tool for artisans and manufacturers alike. Whether you're a hobbyist looking to create intricate designs or a business seeking to streamline operation, selecting the best CNC engraver tailored to your specific needs will ultimately determine the success of your projects.

Understanding Different Types of CNC Engravers Available in the Market

When selecting the best CNC engraver for your projects, it's essential to understand the various types available in the market. CNC engravers can be broadly categorized into laser engravers, rotary engravers, and advanced multi-function machines that combine multiple capabilities. The growth of the CNC machinery market is impressive, projected to surge from $101.22 billion in 2025 to $195.59 billion by 2032 at a compound annual growth rate (CAGR) of 9.9%. This expansion reflects the increasing demand for precision in creative projects, particularly in areas such as woodworking and custom designs.

Laser engravers have gained considerable attention due to their speed and accuracy, making them suitable for a wide range of applications. The laser engraving market alone is expected to reach approximately $6.67 billion by 2035, highlighting its significance within the CNC sector. Moreover, the woodworking CNC tools market is projected to grow steadily, from $8.2 billion to $13.4 billion within the same timeframe, emphasizing the versatility and profitability of woodworking projects. As you explore the different CNC engraver options, consider the capabilities that align with your specific project needs to maximize both creativity and efficiency.

The Ultimate Guide to Choosing the Best CNC Engraver for Your Projects

| Type of CNC Engraver | Material Compatibility | Max Engraving Size (mm) | Precision (mm) | Recommended Usage |

|---|---|---|---|---|

| Laser CNC Engraver | Wood, Acrylic, Leather, Glass | 300 x 300 | 0.01 | Art Projects, Personalized Gifts |

| CNC Router | Wood, Plastic, Soft Metals | 1200 x 2400 | 0.1 | Furniture Making, Large Signage |

| Desktop CNC Engraver | Wood, Acrylic, PCB | 300 x 200 | 0.05 | Hobby Projects, Prototyping |

| Plasma CNC Cutter | Steel, Aluminum, Copper | 1500 x 3000 | 0.3 | Industrial Fabrication, Metal Art |

| Rotary CNC Engraver | Wood, Plastic, Glass | 200 x 200 | 0.02 | Jewelry, Customized Items |

Key Features to Consider When Choosing a CNC Engraver

When choosing a CNC engraver, understanding the key features is essential for ensuring it meets your project needs. Firstly, consider the material compatibility. Modern engravers are designed to work with a diverse range of materials, including wood, metal, and glass, making it crucial to select a model that accommodates the specific materials you plan to use. Look for models that boast versatility while being user-friendly, especially if you’re a beginner.

A vital feature to evaluate is the power output. Higher wattage leads to faster engraving speeds and the ability to cut through thicker materials. Additionally, advanced automation features and intelligent safety mechanisms can enhance your experience, allowing for more intricate designs without compromising safety.

Tips: Always read reviews and user feedback to gauge performance and reliability. Moreover, take advantage of seasonal sales or discounts to get the best value for your investment. Lastly, ensure the engraver offers software that aligns with your creative projects, as this can significantly impact your workflow and final results.

Comparing CNC Engravers: Router, Laser, and Mill Options

When choosing a CNC engraver, it's essential to understand the differences between router, laser, and mill options to find the best fit for your projects. CNC routers excel in cutting and engraving a variety of materials, and recent reviews highlight models like the TTC6050, which offers versatility with the capability to handle wood, plastics, and even PCB materials with its 800W spindle upgrade. Such routers are increasingly popular for DIY electronics enthusiasts who prefer to fabricate and test printed circuit boards at home, as seen with innovative solutions like Biscuit Boards that facilitate rapid prototyping.

On the other hand, laser engravers have gained traction for their precision and speed, making them ideal for intricate designs on materials ranging from wood to acrylic. The latest advancements in laser technology have resulted in hybrid machines that combine both CNC routing and laser engraving functions, thus appealing to a broader range of hobbyists and small business owners seeking multifunctional tools. For instance, emerging products in the market show a growing trend towards all-in-one machines that can effectively address various project requirements, such as engraving detailed artwork or cutting elaborate designs. As reported, the evolution of low-cost CNC solutions has made these technologies more accessible, inspiring a new generation of creators to explore their potential in both hobby and professional contexts.

Evaluating Your Project Needs: Desktop vs. Industrial CNC Engravers

When choosing a CNC engraver, understanding the distinction between desktop and industrial models is crucial for aligning the machine with your project needs. Desktop CNC engravers are typically more affordable and compact, making them perfect for hobbyists or small businesses that engage in low-volume production. For instance, the market has seen new entrants in this domain, such as advanced laser engravers that combine cutting and engraving functions, which not only elevate the craftsmanship but also reduce operational costs significantly. The latest models can deliver innovative products at a fraction of the price compared to traditional machines, making them an attractive option for designers and makers.

On the other hand, industrial CNC engravers are designed for high-volume production and heavier materials, accommodating complex projects that require precision and durability. According to forecasts, the CAx software market is expected to grow from 12.50 billion USD in 2024 to 25.00 billion USD by 2033, citing a robust CAGR of 8.5%. This growth indicates an increasing demand for advanced CNC technologies, suggesting that businesses investing in industrial capabilities will be better positioned to fulfill large-scale projects and meet diverse client needs. As such, selecting the right CNC engraver—based on project scale, material requirements, and budget—can significantly impact production efficiency and product quality.

The Ultimate Guide to Choosing the Best CNC Engraver for Your Projects

Budgeting for Your CNC Engraving Project: Cost Considerations and Options

When budgeting for your CNC engraving project, it's essential to consider not only the initial purchase cost of the CNC engraver but also additional expenses that can accumulate over time. According to a 2022 report by SME (Society of Manufacturing Engineers), businesses overlook factors like maintenance, software upgrades, and tooling, which can increase the total cost of ownership by up to 30%. A well-thought-out budget will include these ongoing expenses, ensuring that your CNC engraving endeavors remain sustainable and profitable.

Additionally, the choice of materials significantly impacts the overall cost of your project. Research from the International Journal of Advanced Manufacturing Technology indicates that material costs can account for up to 40% of the total project budget. Opting for cheaper materials might save money initially but could lead to higher costs in scrap and wasted time if the engraver cannot achieve desired quality. Investing in high-quality materials and a reliable CNC machine can enhance efficiency and better meet your project's demands, leading to greater satisfaction and potential for profit in the long run.

Related Posts

-

Maximizing Your Workspace Efficiency with the Right Cutting Table for Your Crafting Needs

-

Exploring Market Trends: Stainless Steel Laser Engraving at the 138th Canton Fair 2025

-

Exploring Laser Machining Innovations at China Import and Export Fair 2025

-

Unlock Unlimited Possibilities with Custom Laser Cutting for Your Unique Projects

-

Emerging Trends in Stainless Steel Laser Cutting Technologies at the 138th Canton Fair 2025 in China

-

What is the Advantage of Using a CNC Router for Your Business